The Most Popular Trends Among Plastic Preforms

Plastic preforms are an essential component in the manufacturing of plastic bottles and containers. According to Globe Newswire, the global PET preform market was valued at $14.8 billion in 2021. As the demand for reliable and sustainable packaging solutions continues to grow, the technology and trends surrounding plastic preforms are evolving rapidly. This article explores the most popular trends that are shaping the industry today, highlighting innovations and techniques that make plastic preform production more efficient and environmentally friendly.

Sustainability in Plastic Preform Manufacturing

One of the most significant trends in plastic preform manufacturing is the push towards sustainability. Companies are increasingly adopting eco-friendly practices to reduce their environmental footprint. This includes using recycled materials and developing more efficient production methods. The emphasis on sustainability is driven not only by regulatory requirements but also by consumer demand for greener products.

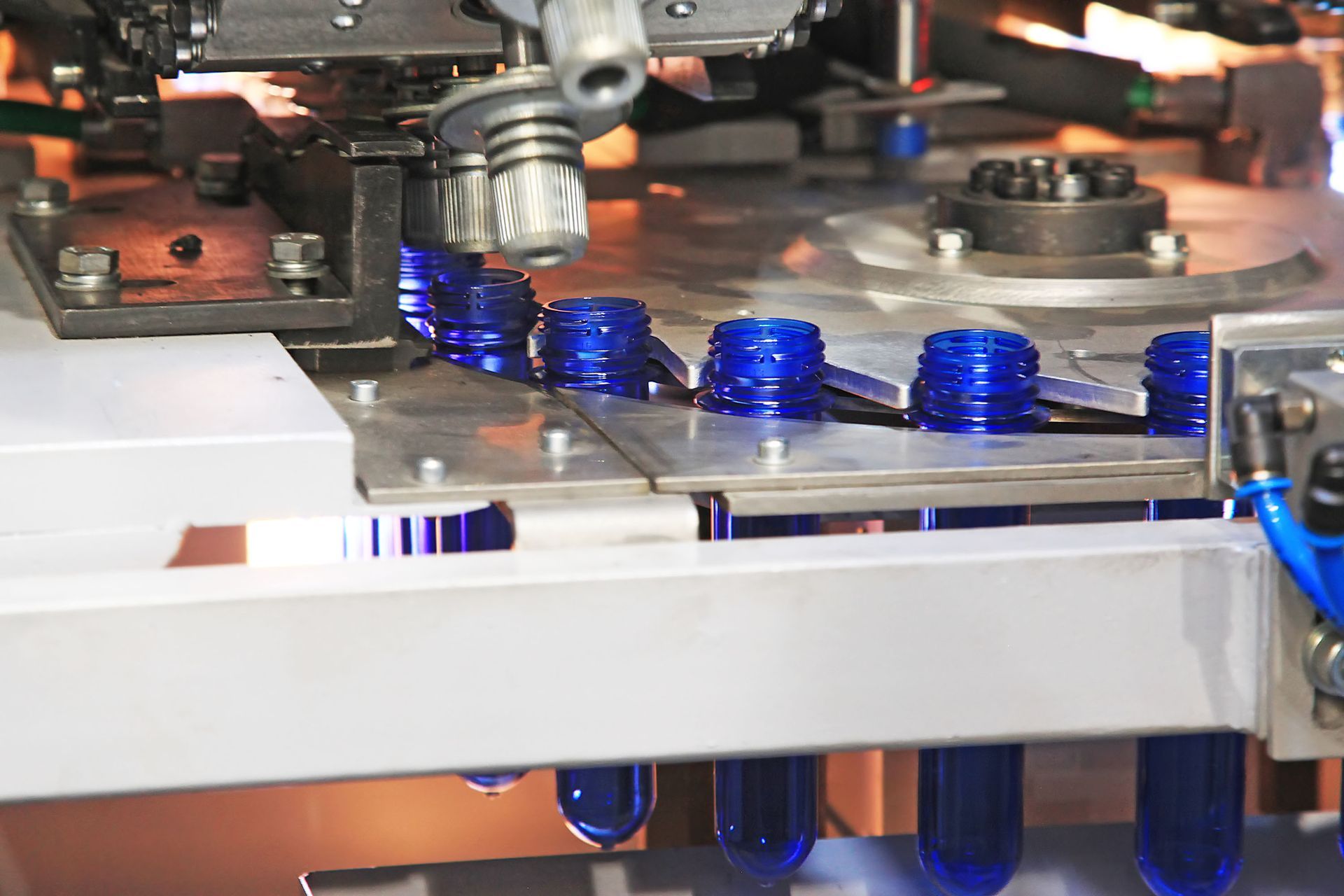

Advancements in Stretch Blow Molding Techniques

Advancements in stretch blow molding techniques have also emerged as a notable trend. There are two types of stretch blow molding techniques: the single-stage and the two-stage process. In single-stage blow molding, the plastic preform is molded and blown into its final shape within the same machine cycle, offering high efficiency and precision. On the other hand, the two-stage process involves separate machines for preform injection molding and blowing, allowing for greater flexibility in production. Both methods have their distinct advantages, catering to different manufacturing needs and scales.

Integration of Smart Technology in Production

Another trend is the integration of smart technology in production processes. The use of automation and real-time monitoring systems is enhancing the efficiency and quality control of plastic preform production. Automated systems can detect and correct any defects during the manufacturing process, reducing waste and improving product consistency. Moreover, IoT (Internet of Things) technologies offer valuable data insights that manufacturers can leverage to optimize their operations and ensure that they meet industry standards.

The trends in plastic preform manufacturing are driven by a combination of sustainability demands, technical advancements, and the adoption of smart technologies. By focusing on eco-friendly practices, refining molding techniques, and incorporating automation, the industry is making significant strides toward more efficient and sustainable production. These innovations not only benefit manufacturers but also contribute to a more sustainable future for packaging solutions. If you're curious to learn more about plastic preform production, contact us at Preform Solutions, Inc today.

Share On: