Debunking Common Plastic Bottle Preform Myths

Plastic bottle preforms are a crucial part of modern manufacturing, yet they remain misunderstood due to several persistent myths. By addressing these misconceptions, businesses can better understand the potential of preforms in achieving both production efficiency and sustainability.

Myth #1: Plastic Bottle Preforms Are Environmentally Harmful

A widespread belief is that plastic bottle preforms contribute significantly to environmental harm. While plastic waste is an ongoing concern, this myth overlooks the positive impact of recycling. Preforms made from PET (polyethylene terephthalate) are highly recyclable, reducing waste when properly managed.

According to the PET Resin Association, over 30% of PET bottles were recycled globally in recent years, though recycling rates vary by region. This statistic highlights the importance of improving recycling systems and educating consumers. With the guidance of

plastic bottle preform consulting experts, businesses can adopt sustainable practices to minimize waste and enhance recyclability.

Myth #2: Preforms Have Limited Applications

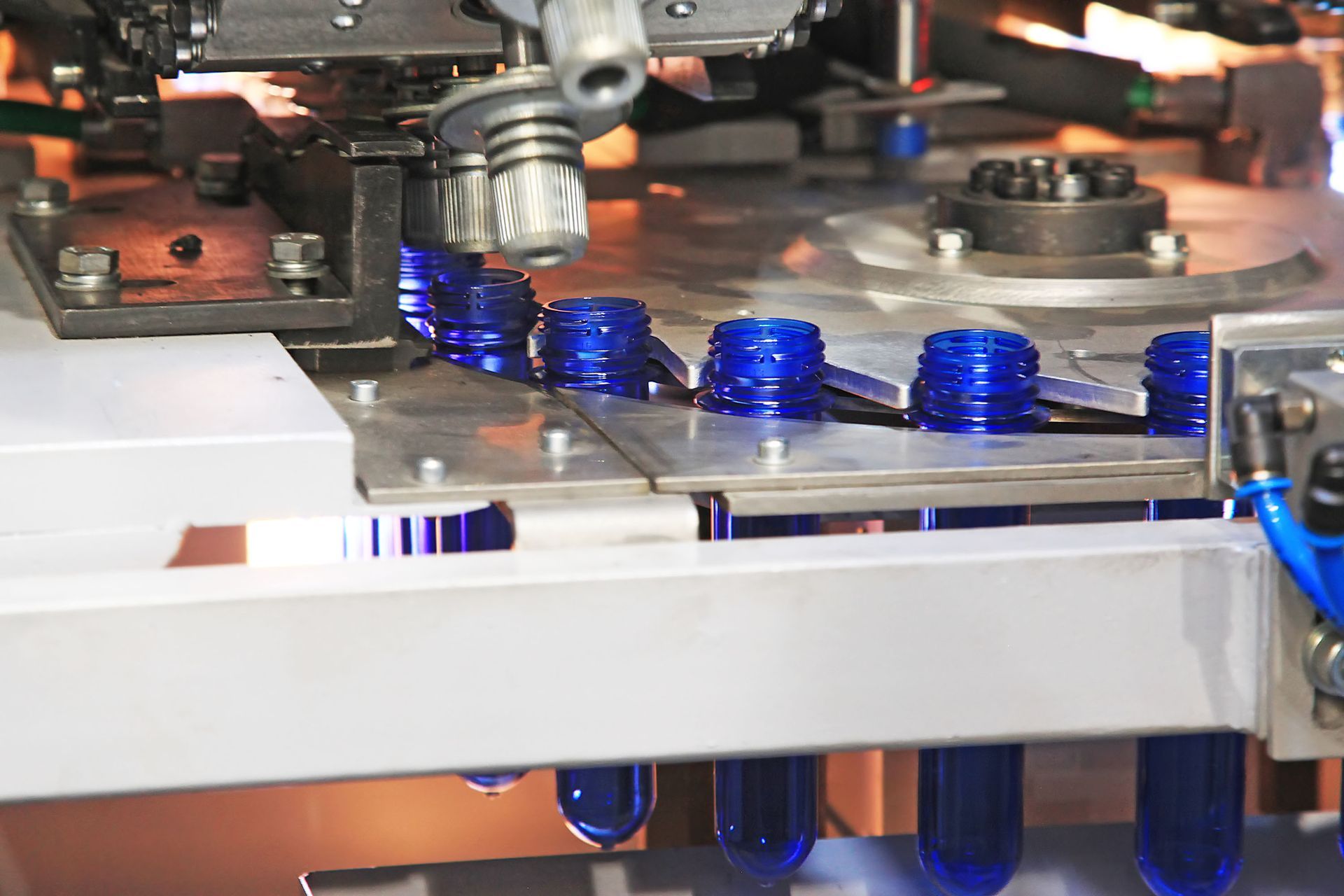

Another misconception is that plastic bottle preforms are primarily used for water and soda bottles. In reality, their applications extend far beyond beverages. Preforms are molded into containers for industries such as cosmetics, pharmaceuticals, food storage, and even industrial chemicals.

This versatility allows manufacturers to meet diverse industry needs with a single production method. By consulting with experts in plastic bottle preform consulting, businesses can explore innovative designs, materials, and production techniques to create specialized preforms for their products.

Myth #3: Preform Production Can Waste Resources

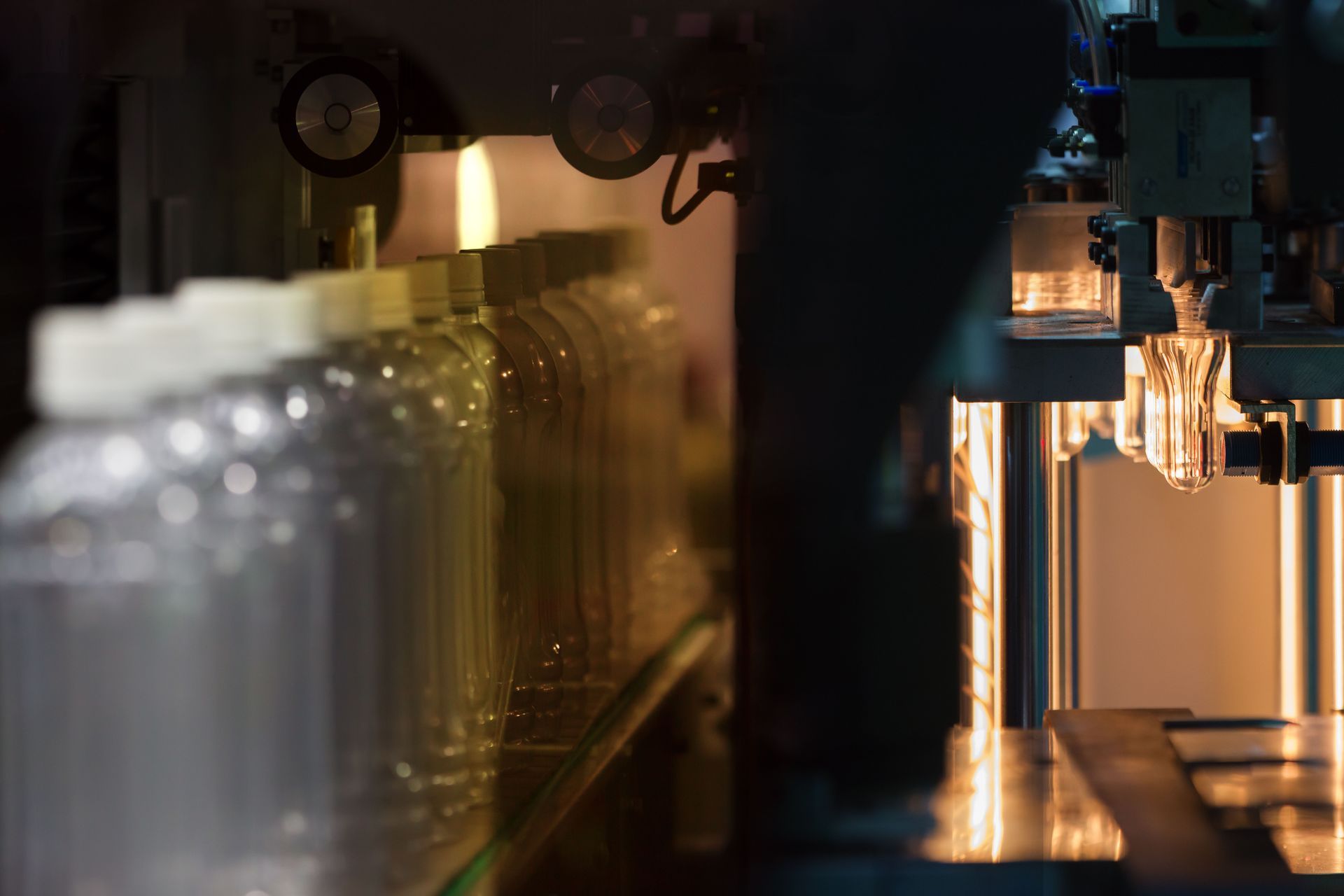

It’s often assumed that producing plastic bottle preforms is inefficient and resource-intensive. However, advancements in manufacturing technology have streamlined the production process, making it both energy-efficient and cost-effective.

Modern preform production methods reduce material waste, optimize energy consumption, and improve output quality. Companies that leverage plastic bottle preform consulting services can identify opportunities to further enhance their efficiency, making production more sustainable and reducing their environmental footprint.

Myth #4: Plastic Bottle Preforms Can’t Be Sustainable

Contrary to popular belief, plastic bottle preforms play an essential role in supporting sustainability goals. PET preforms are recyclable, lightweight, and durable, contributing to a circular economy when properly managed. Businesses that prioritize eco-friendly practices can align their production with consumer demands for greener products while maintaining profitability.

At Preform Solutions, Inc, we help businesses optimize their production processes and implement sustainable solutions for plastic bottle preforms. You can reach out to us to learn how our expertise can elevate your operations and align with your goals. Call our team today!

Share On: