How to Design a PET Bottle Preform for Your Beverage

Developing a custom PET bottle preform for your beverage can help make your brand stand out on store shelves. Follow these tips to create preforms that balance visual appeal, cost efficiency, and functionality. Your brand will stand out like no other!

Consider Your Beverage Type and Needs

PET plastic is used in 70% of fruit juices, soft drinks, dilutable drinks, and bottled water, according to Recycle the One. The first step is deciding if PET makes sense for your particular beverage. Assess factors like carbonation, acidity, oxygen sensitivity, and filling requirements. This will determine the preform design elements needed, like wall thickness, shape, or coloring.

Think About Shelf Appeal

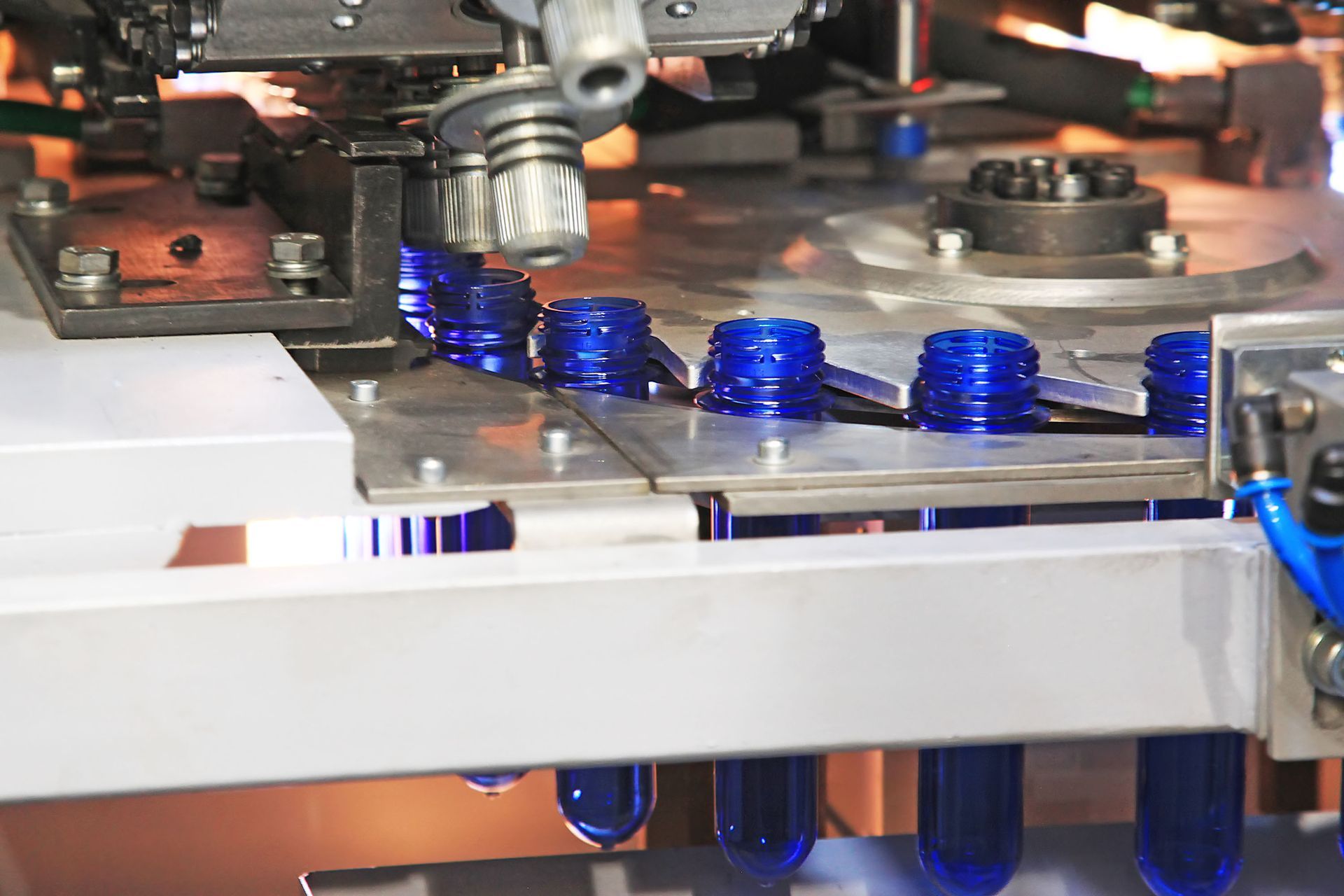

The preform is blown into the final bottle shape, so the preform design directly impacts how your bottles look. Consider factors like shape, width, height, color, texture, and labeling space. Unique shapes or colors can help your brand grab attention. Weigh visual appeal against cost efficiency and functionality as choosing a design that is too ornate can drive up preform and processing costs.

Determine Technical Specifications

The preform must meet technical requirements in terms of material thickness, weight distribution, and tolerances. Thicker, heavier preforms need more PET material and are pricier, but they may be necessary for certain fills. Consider working with PET preform manufacturers and blow molders to determine the optimal preform design to meet performance needs cost-effectively.

Select Your PET Grade

PET comes in different grades with various properties for different applications. Make sure you select the grade best suited for your beverage. For example, choosing a PET grade formulated for hot-fill drinks if you are bottling cold juices can result in problems like deformation down the road. Discuss options with PET bottle preform manufacturers.

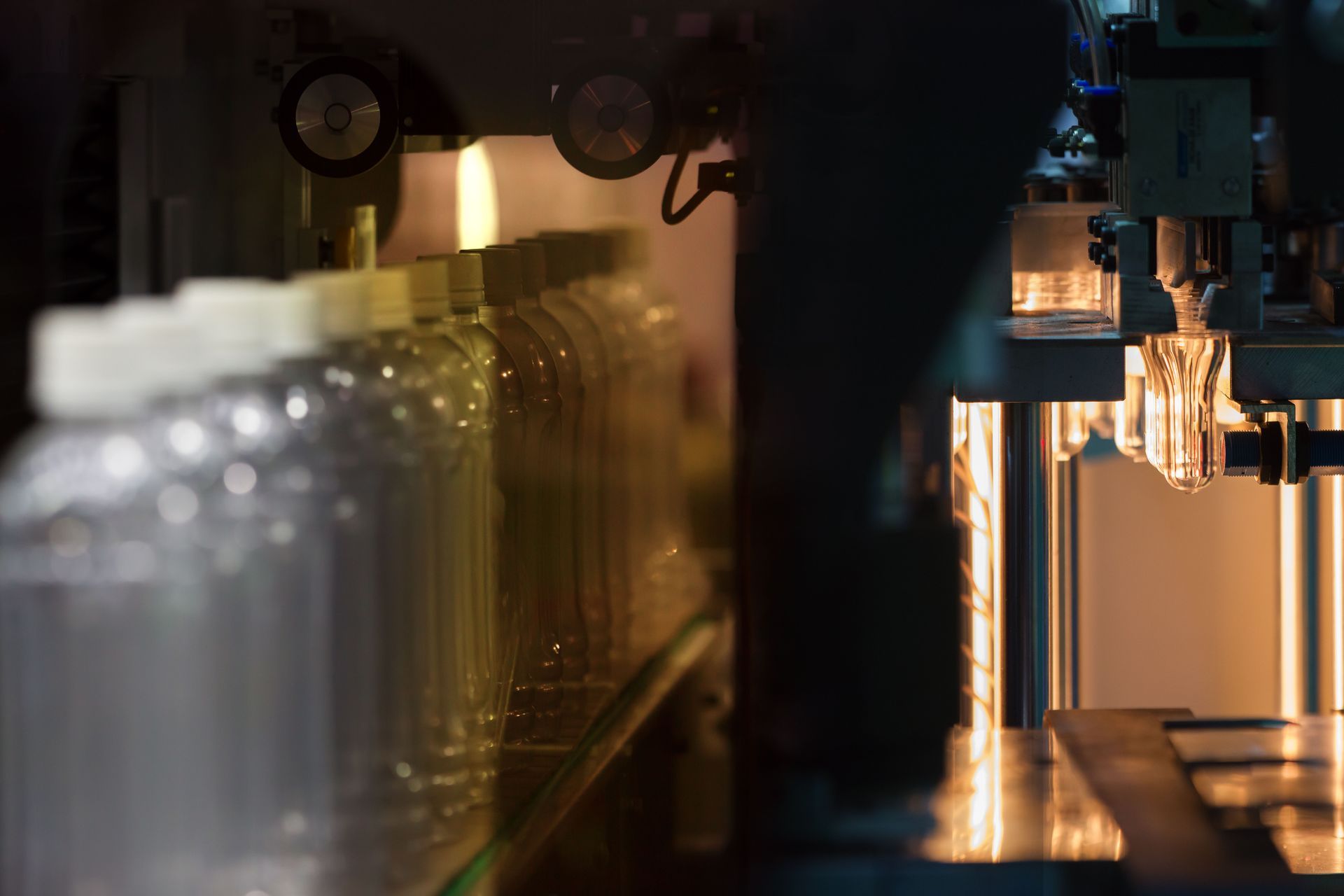

Leave Room for Blowing

Keep in mind the preform will be blow molded into the final shape, so your design needs to account for how the PET will stretch during processing. Preforms usually have thinner necks and thicker bodies to allow for expansion into the final container shape. Partner with blow molders to optimize your preform for proper blowing.

Following these tips will help you develop custom PET bottle preforms that create stand-out packaging for your beverage brand while meeting functionality and cost targets. Leveraging the expertise of PET preform manufacturers and blow molders throughout the design process is key to creating optimal preforms. Call Preform Solutions, Inc to start designing your perfect PET bottle preform.

Share On: