What is PET Prefrom Manufacturing?

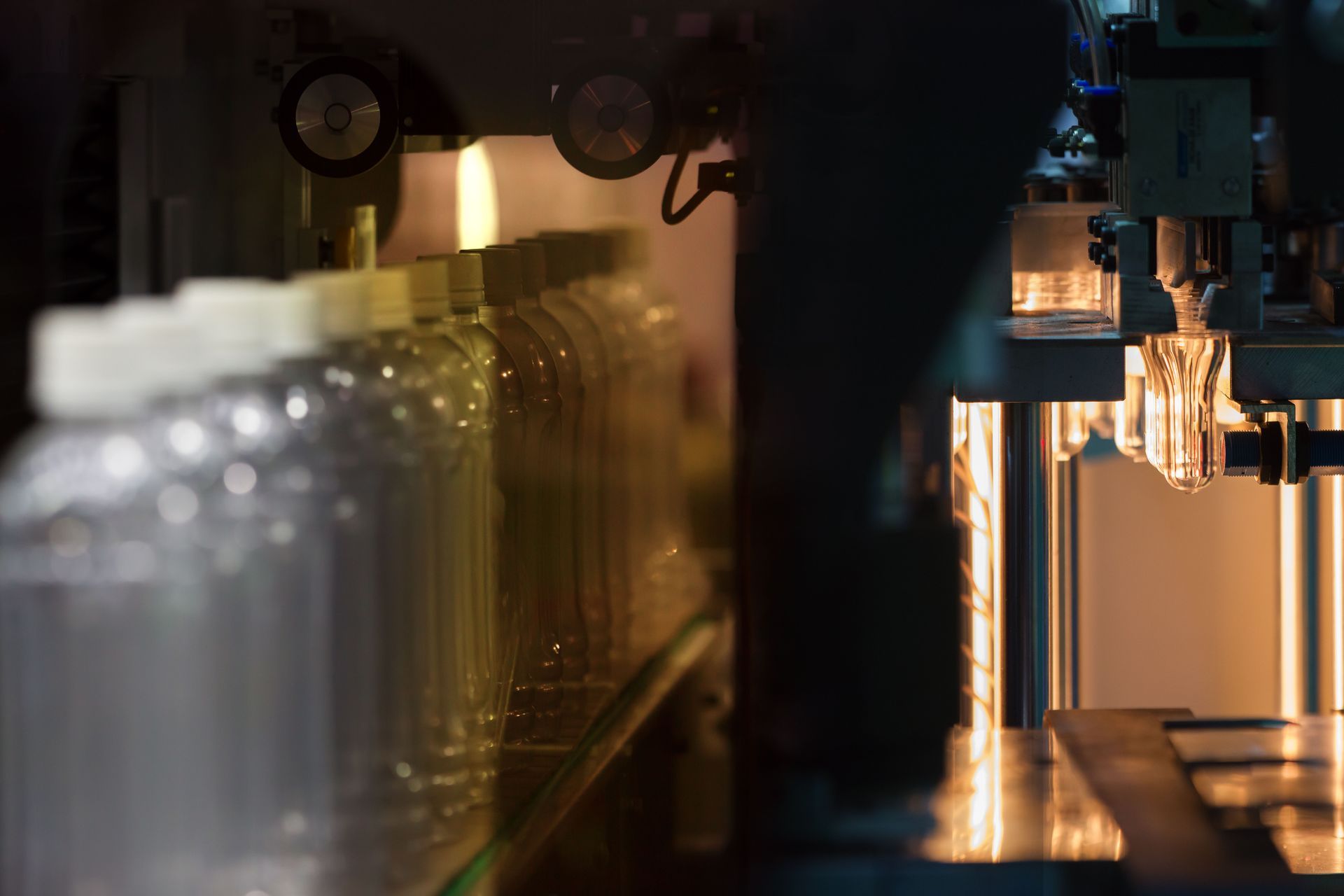

PET preform manufacturing is the process of making and shaping PET sheets, which manufacturers use to produce plastic containers. The process involves the use of stretch blow molding machines. According to O. Berk, you can classify stretch blow molding processes into two types: single-stage and two-stage.

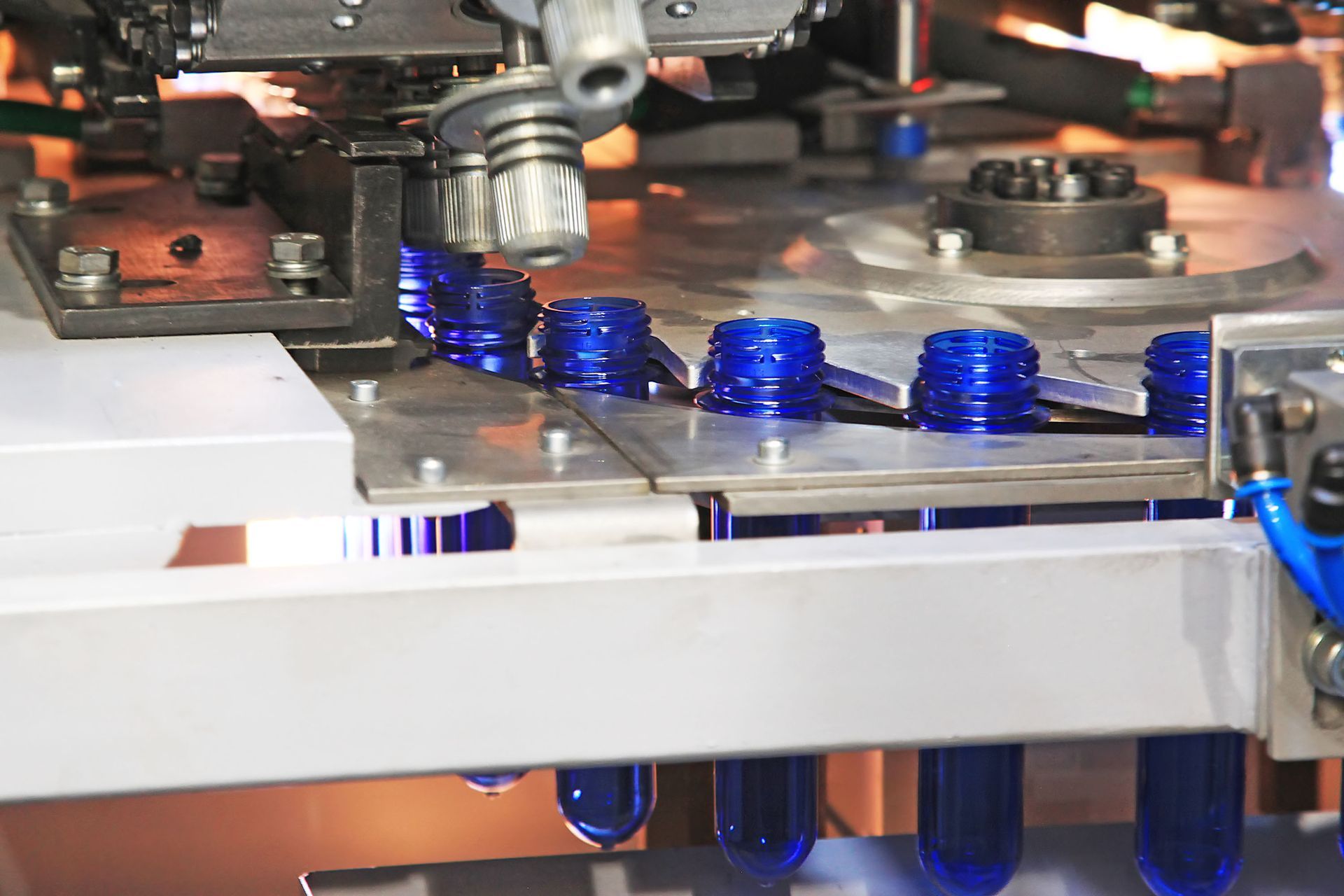

The first step starts with the injection molding machines that shape specific parts of the container. The next phase is the assembly process, where manufacturers put all the necessary components together to form an end product. In this case, they assemble a PET preform into a bottle or other transparent container that can hold liquids or other beverages.

Factors Affecting PET Preform Manufacturing Lines

One of the most critical factors for the success of a PET preform manufacturing line is the quality of preforms it offers. First, the production line must be able to deliver large quantities of preforms using minimal resources.

Second, the quality and integrity of preforms produced should not be compromised because they will affect their performance once assembled into plastic bottles.

Third, there should be consistency in quality from batch to batch and from machine to machine. Inconsistencies can cause bottle defects that will lead to failure during packaging.

Finally, since it already undergoes a lot of pressure and heat during processing, there should also be minimal stress on the PET preform itself.

How To Make PET Preforms More Durable

PET preforms have a high affinity to stress because they are used to hold the finished product with a higher weight than it. To make it more durable, manufacturers can:

- Use the right amount of virgin resin. The right amount will help prevent deformation due to mechanical stress introduced during processing. As much as possible, use only virgin material in manufacturing PET preforms because it is purer and more rigid.

- Use the appropriate technology. Some technologies produce thinner sheets like the blow torch, which manufacturers operate manually. Others make thicker sheets using machines like extrusion lines that use various equipment to compress and heat resin until they become thinner sheets or preforms.

- Use the right equipment. Some equipment like injection molding machines produce preforms that have consistent thickness. Others, like extrusion lines, make sheets with varying thicknesses from top to bottom because of how the resin is handled and pushed through the line.

Manufacturers use PET preforms to produce bottles and other containers. To ensure they are as good quality and durable as possible, they must subject them to various tests before incorporating them into production.

If you are looking for the best PET preform manufacturing line, don't hesitate to contact Preform Solutions Inc.! We will get back to you as soon as possible. We are one of the leading PET preform manufacturers in South Dakota. Our PET preforms are of high quality and competitive price. Visit our website or call for more information.

Share On: